- Articles

- 30 May 2025

Building Rail Excellence: Where Cutting Edge Technology Powers a Maintenance-Focused Culture

How innovation and the smart use of technology augment ComfortDelGro’s edge in the rail business, enhancing customer experience, safety and inclusiveness

Since the launch of Singapore’s North East Line (NEL) in 2003, as the world’s first fully automated and driverless heavy rail metro system, ComfortDelGro and its subsidiary SBS Transit have continuously adapted and advanced with the latest technological developments. The team develops increasingly refined methods that use data and analytics to predict trends and avoid potential issues before they arise. This smoothens out operations, in line with its principal goal to achieve a superior commuter experience.

“We are deeply committed to reliability, which is the key focus of our operations,” explains Jeffrey Sim, Group Chief Executive Officer of SBS Transit. The company has built a culture around impeccable maintenance standards, where technology and data are the enablers.

With progress in Artificial Intelligence (AI) gaining speed, organisations around the globe are sharply increasing spending on technology. Digital transformation, however, is not just about investment; it also requires a blend of adequate processes and the right culture to maximise value.

Better insights for more reliable train operations

“What differentiates us is our maintenance ethos,” says Sim. “It’s the mindset, the emphasis on asset management and the way we make the assets work better and more efficiently that sets us apart.”

ComfortDelGro adopts a notably different strategy compared to other rail operators. While non-autonomous systems are designed with a focus on human interaction, the company’s system emphasises reducing human intervention to enhance reliability and minimise the likelihood of breakdowns. It manages machines through a data-driven approach rather than relying on extensive personnel training.

The results consistently show up in the numbers. The Downtown Line (DTL) continues to lead and set benchmarks within the official “uptime” statistics, achieving over 8 million train kilometres between failures, as per the most recent Land Transport Authority of Singapore’s data. Both the DTL and NEL have seen incremental improvements in reliability, and no more than one network outage per year that exceeds five minutes.

The company’s Maintenance and Engineering Centre (MEC) plays a central part in that effort. The MEC collects and analyses the data that contains valuable information on the robustness of the operation.

While the Operational Control Centre (OCC) directly manages the smooth functioning and safety of the newest GoA4 generation of autonomous trains. The team continuously monitors all assets and provides real-time alerts to the OCC when certain operational thresholds are exceeded.

Using two internally developed data aggregation tools, named 4sight and 6sense, anomalies are detected, enabling pre-emptive responses to prevent train failures. These tools address interface defects between the rolling stock and train-borne signalling by utilising time-synchronised data. 6sense offers a comprehensive health analysis of the entire fleet, considering each train’s corrective maintenance history and alarm counts. Additionally, it can identify emerging alarm trends and further enhance predictive maintenance practices.

The age of automation

Robotics isn’t fully replacing physical inspections quite yet, but they are an increasingly common sight in ComfortDelGro’s operations. The multifunctional track trolley “RailRover” detects cracks in tracks and water leaks in tunnels. Trials involving an autonomous AI robot dog are ongoing, allowing for more accurate checks in areas that are difficult to access.

SBS Transit also developed a Permanent Way Defect Management and Analysis System (PDMAS) for its track and tunnel monitoring, including a digitalised defect recording process that feeds directly into 6sense.

Sensors, meanwhile, play an increasingly dominant role. “They can detect anomalies such as high usage of energy in point machines and signal boxes, which could indicate potential issues,” explains Koh Boon Yeow, Head of North East Line and Sengkang-Punggol LRT. “They also allow us to identify defects like hot axle boxes and high wheel impact loads early and take action accordingly.”

Newer trains now come equipped with condition monitoring systems that enable the remote monitoring of critical components and send alerts on impending issues.

With the data collected from sensors, the MEC can plot graphs that track train speeds and braking intensity along the track, enabling them to deduce how much energy is used on a specific stretch of the network.

Insights like these are extremely valuable when it comes to increasing power efficiency and reaching green transformation goals. SBS Transit is currently running tests with regenerative braking to recycle it for acceleration, this is expected to save up to 3,000 MWh a year.

Advancing workforce capability and safety

While advanced maintenance practices drive operational reliability, empowering staff with the latest technology further enhances these efforts.

Technology is playing a more direct role in supporting maintenance staff and drivers during daily operations. Portable AI-powered devices help monitor and track conditions and ensure drivers stay alert and well-informed. Connecting Stockholm, the joint venture company that will operate the metro in Stockholm from late 2025 will be deploying an advisory system for drivers to make sure they are not accelerating too much, helping them meet energy consumption targets.

Improved technology has already led to greater workplace safety, reducing injuries company-wide by 5 percent. Virtual reality simulators are now more often part of staff training and safety programmes, creating a more realistic rendering of the working environment.

SBS Transit uses high-resolution simulations and VR goggles equipped with eye tracking. “Mixed reality visualisations allow us to improve safety habits and replicate best practices in the field,” says Markin Lai, Senior Manager of Rail Training Development at SBS Transit. The company’s Track Access Management System, which allows for efficient booking, planning, and allocating of access for maintenance works, was recognised at LTA’s Public Transport Safety and Security Awards 2023 and the Singapore Business Review Tech Excellence Awards 2024.

A better and more inclusive user experience

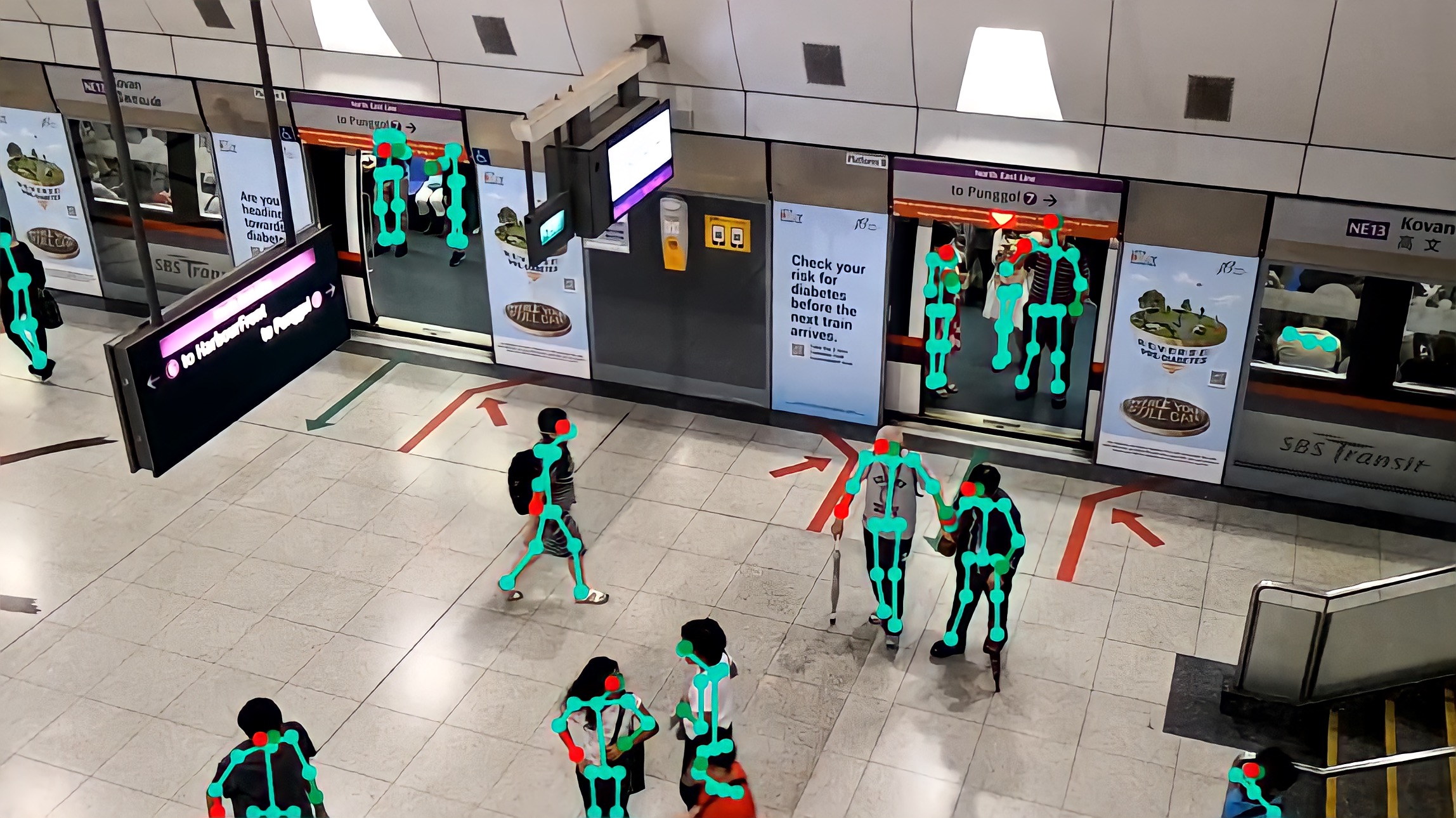

Modern CCTV systems now help to automate the detection of track intruders, improving safety for both staff and customers. “These advancements are what clients expect from us as a leading operator and we are committed to delivering solutions that make operations safer, more efficient and cost-effective,” said Sim.

CCTV is also used to spot overcrowding in stations and to adapt train schedules for the convenience of daily commuters. A software developed in collaboration with Siemens Mobility analyses crowd level on trains and within stations, facilitating dynamic timetable adjustments based on real-time demand.

These days, the digital revolution promises to bring even more innovative and inclusive applications for travellers. SBS Transit, for instance, has partnered with navigation technology firm Waymap to develop an audio-based wayfinding app specifically designed for users with disabilities.

“Trains will not only become more convenient but also more reliable as we continue to leverage technology and innovation to meet the evolving needs of our customers,” Sim concluded.

This is the first article of a multi-part series featuring ComfortDelGro’s rail business and all information is accurate at the time of publishing.

Discover how our rail expertise is making its mark globally — read The Singapore experience goes global: Building on two decades of excellence in the rail industry.